Amazon has put together some great Home Gift Deals – save money and get your shopping done at the comfort of your home! Click here to see deals on Amazon

Have you ever lost keys to your bike or the lock of your fence, and you need to get access right away?

Well, if that happened to you, then you are not alone. By having the best bolt cutters in your toolbox, you can get access right away, albeit destroying the lock. A bolt cutter is an invaluable tool for different variety of tasks.

After all, it can be a lifesaver when in urgency. Bolt cutters vary from small regular size to heavy-duty for cutting stronger and thicker objects. To help you make a decision, we’ve put together our list of the best bolt cutters for any kind of locks and fence.

Keep reading to learn more about it and learn the details of some of our favorites, but if you’re in a hurry, have a look at the quick picks below!

Quick Picks

We may earn a small commission, at no cost to you, when you buy from our link to support us. More

Crescent PowerPivot

Sturdy and reliable bolt cutter which can chew any thicker metal like butter. The high-cutting leverage design needs 30% less effort than others.

Ridgid Heavy Duty

The bolt cutter with no hold barred. Lost lasting and comfortable to cut any type of metal. Wide flexibility in size from 19 to 38 inches. Perfect for cutting any soft to hard material.

Tekton Bolt Cutter

The drop-forged hardened alloy steel jaw is perfect for cutting any bolts, chains, and locks. Lightweight and sturdy grip handle mean business without breaking a bank.

5 Best Bolt Cutters Available Today

Product

Name

Detail

Price

- 18 and 24 inch size

- 19, 24, 31, 38 inches

- 12 to 42 inch size

- 14 inches

- 8 to 36 inch size

Our Top Pick

This is one of the best bolt cutters on our list that can cut through most of the locks, including master locks. The stronger and hardened steel jaws can easily cut through most metals.

For flexibility, you can buy it from 19 inches to 38 inches in size that is perfect for cutting soft, medium, and hard materials. It has a cutting capacity of 5/16 inches to 1 inch.

What’s a Bolt Cutter?

Bolt cutters are used to cut any strong metal piece which you can’t cut through a regular slicer. Most often, it’s used to cut wires, padlocks, bolts, or chains. The key to its performance is its long handle and durable short blades.

The blades are typically made from hardened carbon steel that does not bend or get dull when used to cut thick metal objects. The long handle provides enough leverage to the blade to cut the metal piece.

There are lots of different designs and styles of bolt cutters available depending on the intended use and the maximum cutting thickness. The cutting happens by applying immense pressure at a small point.

Typical bolt cutters can apply up to 20 kilo-newtons of a powerful force, which is enough to cut most steel padlocks.

What to consider when buying bolt cutter

Cutter Size

Cutter can range anywhere from 12-45 inches. For most residential use, a size between 26-38 inches works best.

Blade

For durable and long-lasting performance, choose stainless steel blade that remains sharp even after a tough cut.

Cutting Adjustment

For greater flexibility, choose a bolt cutter that allows you to adjust the cutting diameter for thicker material cuts.

Have a question about buying a bolt cutter? Contact us

Best Bolt Cutters Review

1. Crescent PowerPivot Compound Action Bolt Cutter

Best Bolt Cutter For Hardened Steel

For cutting hardened steel, you need a tool that you can trust. This tool comes in two different sizes, 18 inches for cutting soft to medium-hard materials and 24 inches for thicker hard materials.

Whether you need to cut bolts, chains, wires, padlocks, or threaded rods, you can rely on the cutting power of this bolt cutter. With an 18-inch bolt cutter, you can cut thickness up to 9/32 inches, whereas a 24-inch bolt cutter can cut 5/16-inch thicker materials.

The reason for this highly efficient cutting performance is due to its advanced proprietary cutting design called PowerLink. This allows higher cutting leverage that needs 30% less effort than other bolt cutters.

The tubular steel handle and forged lever design allow the bolt cutter to withstand the harshest working environment. It’s rated to use on rods, screws, chains, baling wire, electric wires, chain link fences, and padlocks.

See More information on Crescent PowerPivot Compound Action Bolt Cutter

Pros

Cons

2. Ridgid Heavy Duty Bolt Cutters

Best Bolt Cutters For Locks

Do you need to cut the hardened steel of master padlocks?

Then give this bolt cutter a chance. It has hardened alloy steel jaws that can chew through indestructible metals.

Ridgid is one of the oldest tool manufacturers founded in 1923. A company that lasted close to a century knows how to build a quality product. The bolt cutter is sturdy and made to last longer. The hardened cutting blades improve the life, strength, and durability of the bolt cutter.

The handle is durable but lightweight and has a comfortable grip cover. For more accurate cutting, the one-step internal cam mechanism provides a quick and straightforward way to maintain precise blade alignment.

It comes in from 19 inches to 38 inches in size, which is perfect for cutting soft, medium, and hard metals with cutting capacities ranging from 5/16 inches to 1 inch.

See More information on Ridgid Heavy Duty Bolt Cutters

Pros

Cons

3. Neiko Heavy Duty Bolt Cutters

Best Heavy Duty Bolt Cutters

Neiko Heavy Duty comes in 7 different sizes ranging from 12 inches to 42 inches. The blade is made from Chrome Molybdenum steel that cuts through hard and more robust objects without getting dented or chipped away.

The heat-treated blades improve the durability and reliability of the tool. The unique lever-fulcrum design provides the most possible leverage with less effort. The ergonomically designed textured handle feels comfortable to hold and does not put much stress on the hand.

For greater flexibility, you can easily adjust the blade clearance by turning the two eccentric bolts at the tool’s head. You can cut ¾ inch thick standard metal bar with ease.

If you are trying to cut a master lock, people have mixed experiences. For greater success, always try to cut the lock at a right angle and don’t twist or turn the blade when applying pressure. This causes the blade to bend and chip away the jaw.

See More information on Neiko Heavy Duty Bolt Cutters

Pros

Cons

4. ToughBuilt Compact Bolt Cutters

Best Bold Cutters For Padlocks

If you are looking for a compact bolt cutter that you can take with you anywhere, then this bolt cutter may be the right choice. To save space, it folds in half and can fit most tool boxes or bags.

This increased mobility does not mean that you have to compromise on the cutting efficiency. The strong and durable cutting jaws mean it will cut the most common types of padlocks in no time.

For example, you can cut through ¼ inch padlocks with some effort. However, the small size means this won’t be suitable to cut thicker and hardened steels. You should be looking for heavy-duty bolt cutters with longer handles for that kind of task.

The rubber-coated handle makes it smooth and comfortable to hold the cutter. The extra-wide handle makes it easy to carry with a single hand. The use of durable and high-quality steel means it won’t get chipped or dull easily.

Overall, this is a useful tool for regular use, such as cutting padlocks, wires, and chains. Although it’s designed to be mobile use, it doesn’t come with any carrying case.

See More information on ToughBuilt Compact Bolt Cutters

Pros

Cons

5. Tekton Bolt Cutter

Best Bolt Cutters For Cutting Locks

Tekton Bolt cutters have drop-forged hardened alloy steel jaws that are perfect for cutting any bolts, chains, threaded rod, and locks. The sturdier and wide opening jaws have a cutting diameter of 5/16 inches.

The well-designed cutting jaws deliver superior cutting power with the least amount of effort. The tubular handle gives you long enough length for greater leverage without getting the bolt cutter heavy.

The soft rubber grip handle is comfortable and doesn’t let the cutter slip from the hands. The slimmer jaw profile makes it easy to reach obscure places and increases cutting precision. Tekton bolt cutters certainly get the job done most efficiently.

Overall, if you need versatile bolt-cutters that can also cut through most locks and stand up to rugged conditions, then the Tekton bolt cutter is the right choice.

See More information on Tekton Bolt Cutter

Pros

Cons

Features of a Reliable Bolt Cutter: What To Look For

Bolt cutters should be strong and durable and should be able to get the job done. With that in mind, here are some features to look for when considering any bolt cutter.

Bolt Cutter Size

Bolt cutters come in different sizes. Most often, the size is measured from the tip of the handle to the blade edge, which can range anywhere from 12 to 45 inches.

If you are buying bolt cutters for personal use, then it’s more likely you may be intended to use them in cutting home locks, gyms lockers, and storage lockers.

Most of these locks and chains are generally ¼ inch in diameter. For these use case scenarios, buy a 24-inch blot cutter, which has a cutting capacity of 5/16 inches. For cutting thicker locks and chains, you can use bolt cutters that are 26 to 38-inch long.

Keep in mind that the longer the size of the bolt cutters, generally the thicker metal bars you can cut. However, larger size bolt cutters also become bulky and heavy, so choose the right size based on your needs.

Cutting Type

You can make different types of cuts with bolt cutters such as angle cut, clipper cut, center cut, or shear cut. The type of cut dependents on the kind of material and how it’s hardened.

For example, if you have to cut the metal fence, then you should use clipper cut style bolt cutters, which are usually lightweight and more comfortable to handle. But if you have to cut strong flat bars or chains, then pick a bolt cutter that can do the angle cut and has a more extended handlebar for better leverage.

Bolt Cutters Blade

The quality of the bolt cutter blade determines how easily you can cut the metal piece, and how long it may last. The blade quality depends on the material used in making a blade, the technique used to harden it, and the design of the module.

Most cutter’s blade is made from stainless steel as its robust, durable, and prevent rusting. To further harden these blades, so it does not get blunt after repeated use, these blades are heat treated.

In heat treatment, the steel is heated at a high temperature and then quickly cooled down. This process is called quenching, and it results in stainless steel getting hard but not brittle.

Bolt Cutter Handle

Using an ergonomically designed bolt cutter handle makes it easier and comfortable for cutting. It also improves leverage and handgrip when cutting thicker locks or wires. Using a long handle that provides the best leverage and a good weight to length ratio is an important consideration.

The handle material can be either made of aluminum, steel, or cast iron. For a lightweight and sturdier option, the aluminum-made cutter handle works best.

To reduce the chance of blisters when using a bolt cutter, look for the material used in the grip handle. A sturdy non-slip grip handle made of rubber is generally the best option.

Cutter Adjustability

For greater flexibility, using an adjustable bolt cutter allows you a broader cutting range. The adjustable bolt cutter cuts through different thicknesses and materials. This means you don’t need to carry multiple spare or different-sized bolt cutters.

This saves money and takes less storage space. For longer life of bolt cutter, always keep it clean and oil it regularly. It prevents rusting of the blades and adjusting joints. Some bolt cutter models also allow you to remove the modules from the handle that making it easier to clean.

How To Use A Bolt Cutter To Cut A Lock Or Wire

The use of a bolt cutter may appear straightforward. But if you want to get a cleaner cut with less effort, then you need to think ahead before you start a cut.

Know The Lock Thickness

The first thing before cutting a lock is to know the thickness of the lock bar. This will determine the correct size of the bolt cutter required to make a cut.

For most average-size locks such as lock pads, bicycle cables, chain link fencing, or wire, the regular-size handheld cutter may work.

For thicker and heavy-duty chains or objects, you may need a longer handle bolt cutter.

Prep The Area

You must take adequate safety precautions when cutting any metal piece. Clean out the surrounding areas before you start a cut to prevent any mishaps.

Metals, when squeezed, tend to snap or fly out. These loose metals may either hit other loose particles or hit you directly.

Cleaning or securing any loose objects from the cutting area minimizes accidental fly-outs. You can also wrap the cutting jaws with a cloth to catch any flyouts. At last, never attempt to cut a live electrical wire with a bolt cutter.

Adjust The Cutting Angle

Determine the cutting angle for an optimal cut. Sometimes it may not be possible to pass through the cutting blades through a particular perspective due to obstructions or the position of the cutting object.

Find a comfortable cutting angle as it helps with a better cutting allowance that is essential for a cleaner cut.

Note:

For cutting thicker objects, use a longer handle bolt cutter for higher leverage.

Using A Bolt Cutter

When you are ready for the cut, put on proper safety gear such as gloves and safety glasses. Once you are prepared for the cut, place the bolt cutter jaw at the correct cutting angle. Open the cutter jaws as much as possible to allow the metal piece to go through the blade.

In some instances, it may be easier to make a cut in the middle rather than at the edges as it allows you more room to adjust the jaw. The blade should be aligned at the right angle to the object. Don’t attempt to make an angled or diagonal cut as it may cause the blade to twist or slip.

Once you have the blade grip firmly on the object, start applying pressure on the handle. Grabbing the handle at the edge allows you maximum leverage.

You may need a couple of attempts in the cutting. If you are not able to cut in the first attempt, open the jaw again, adjust the angle a bit and position the jaws at the same place.

Don’t try to find a new cutting location unless absolutely necessary otherwise you will have to make more effort in cutting.

You should be able to cut the lock in two or three attempts. But if you find that you still cannot cut it, then try to get better leverage.

If it’s possible to support one handle on the side or to the ground, then use it to your advantage when applying pressure. You can also use handle extension or pick a large-size cutter if you still have difficulty making a cut.

What Size Bolt Cutter To Use To Cut A Padlock?

The size of the bolt cutter depends on the hardness of the material you are planning to cut. This hardness is rated on the hardness rating scale (HRC). Some products also have this hardness expressed on the Brinell and Rockwell scales.

There are primarily three different sizes of bolt cutters.

- Compact size bolt cutters: The compact bolt cutters are smaller in size and are generally 8 inches to 14 inches long. These are good to cut soft and medium-hard materials with different hardness ratings ( Brinell 300 – 455 or Rockwell C31 – C48 ). You can cut padlocks, chains, or bolts up to maximum 1/8 inch in diameter.

- Medium size bolt cutter: The medium size bolt cutters are 18 inches to 24 inches long. The longer handle length means you get better leverage and can cut similar hardness material but thickness up to 3/8 inch in diameter.

- Large size bolt cutters: The larger size bolt cutters are 30 inches or longer in length and can cut objects thicker than 3/8 inch in diameter. The cutting success depends on the hardness of the object and the design of the bolt cutter. The longer handle provides increased leverage.

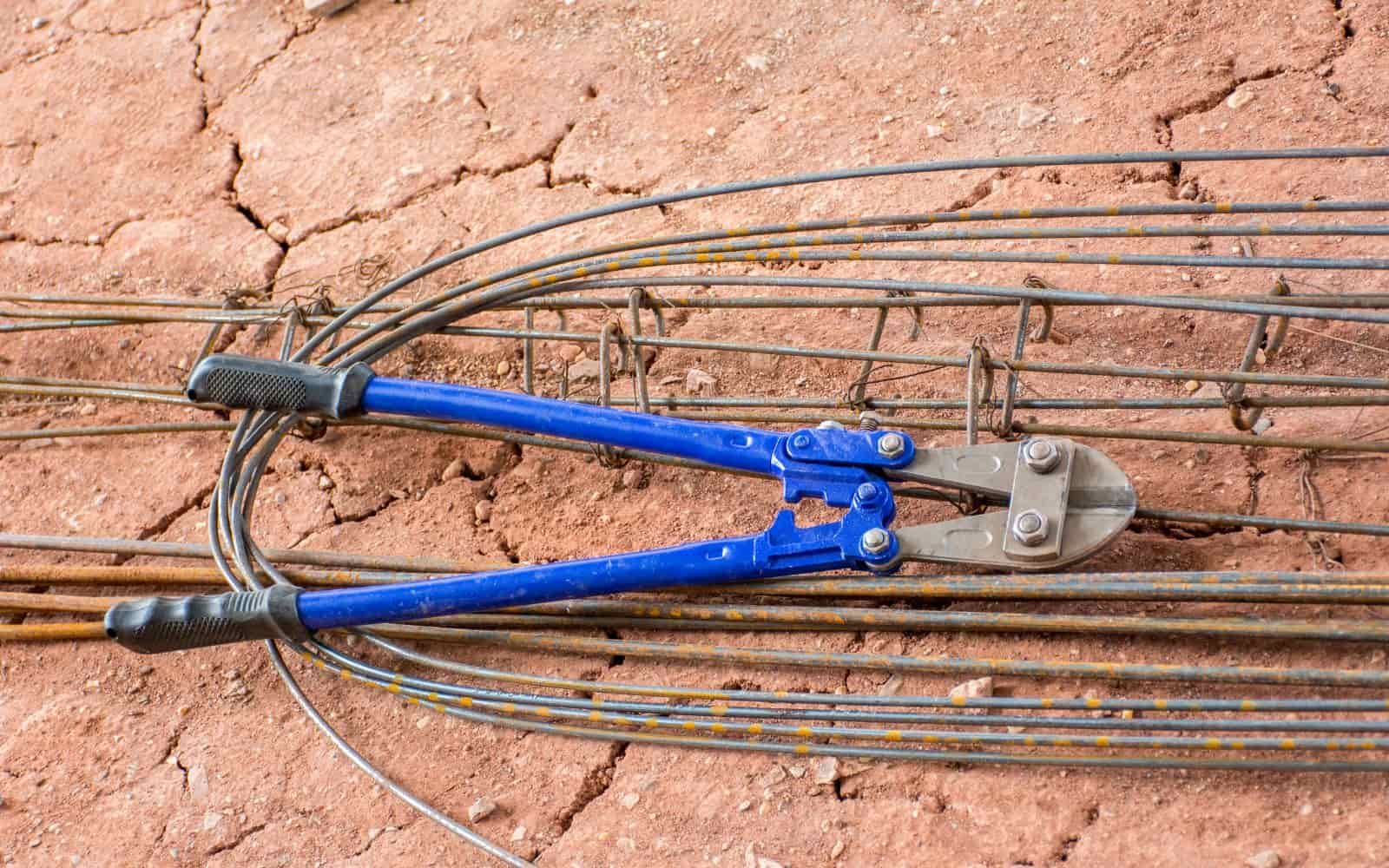

Will Bolt Cutter Cut Rebar?

Bolt cutters can cut most of the metals object, including rebar. The success depends on the hardness and thickness of the rebar. Always know the maximum cutting rating of the bolt cutter before you attempt to cut. Using a low-rated bolt cutter to cut thicker objects may cause the bolt cutter to break down.

As a general guideline, for cutting rebars, use bolt cutters that have forged steel blades with hardened steel edges. Keep in mind that you may not always get the cleaner cut with a bolt cutter.

If your main goal is to remove the object, then this works best, but if the aesthetic of the cut is necessary, then use other cutting methods such as sawing off the rebar.

An able-bodied person can apply up to 4 thousand pounds of cutting pressure, which is enough pressure to cut through most household or construction materials. Some hydraulic bolt cutters, most commonly used by emergency workers, can apply up to 16 thousand pounds of cutting pressure.

How To Sharpen Bolt Cutter

There are several different ways to sharpen a bolt cutter. It all depends on the type of blade and its construction material. You can use an angle grinder or mill file to sharpen the bolt cutter.

Make sure to clean the area from any debris or rust particles. For a smaller size bolt cutter, use a mill file to sharpen the blades. For a longer and larger size bolt cutter, use an angled grinder to sharpen the edges.

Use grip jaws to hold the bolt cutter firmly when using an angled grinder. If you don’t have grip jaws, then you can hold the bolt cutter in between objects and file it at a 20 to 30-degree angle.

When sharpening bolt cutters, don’t make the edges too sharp. The bolt cutters’ primary objective is not to slice through the material but rather apply highly pointed pressure to break.

Keep the blade slightly rounded off at the edges. This prevents the blade from buckling and denting which helps with cutting objects without damaging the blades.

Once you have finished sharpening the blades, use a brush and cleaner cloth to remove any leftover and fine metal particles. You can also lubricate the blade and the handle with lubricating oil, which prevents rusting and reduces cutting friction.

Don’t forget to share this post